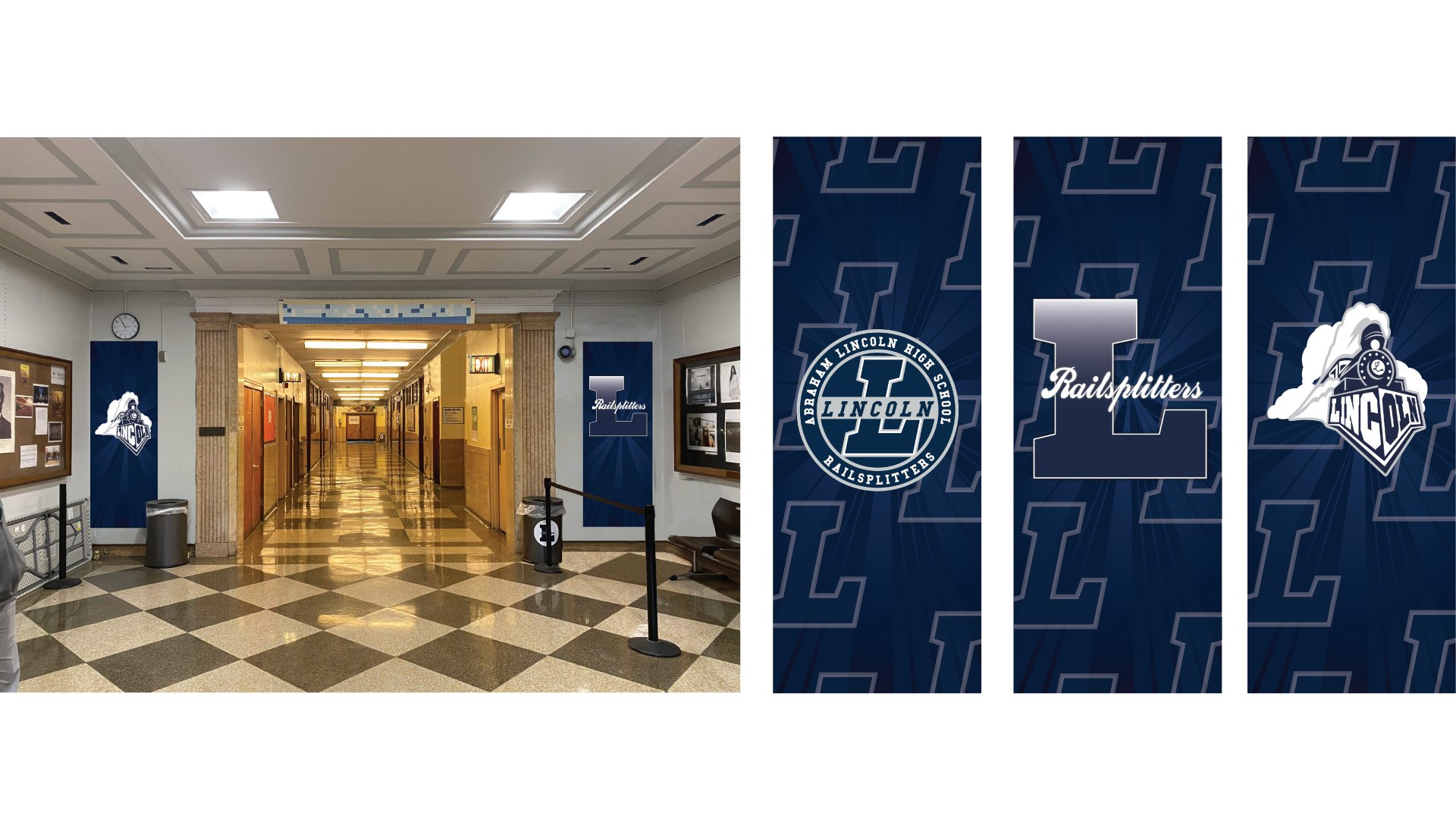

ART DIRECTION

PRINT PRODUCTION

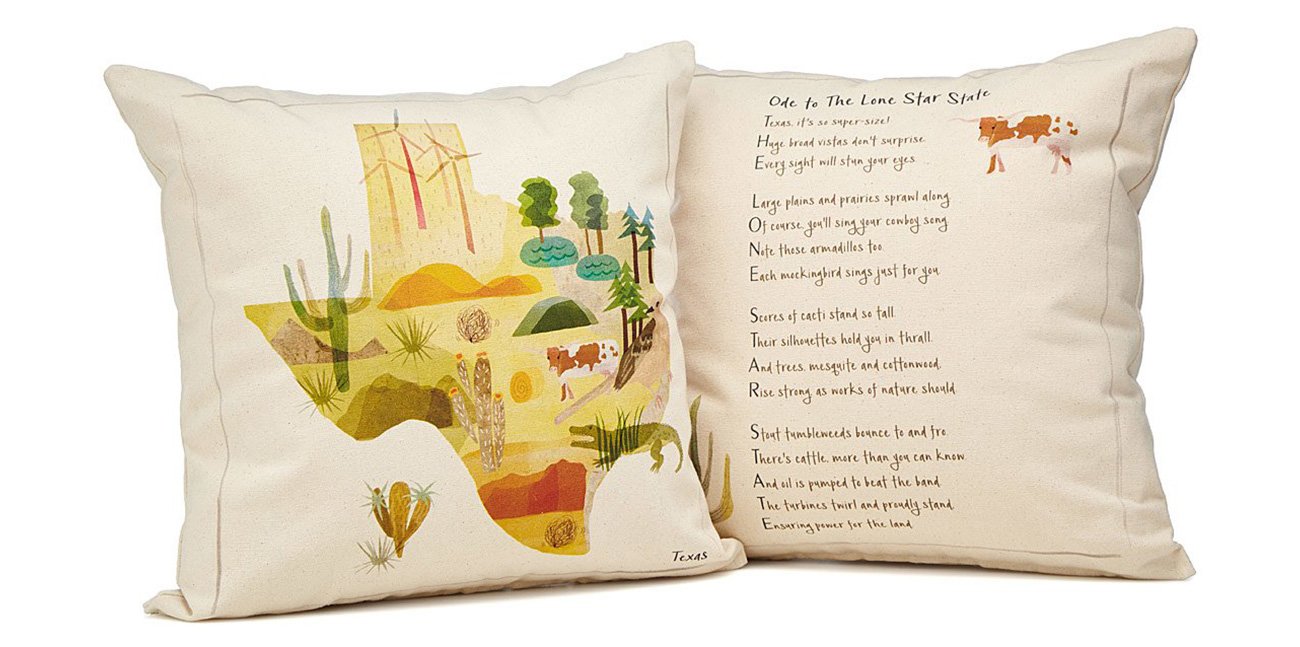

PRODUCT DEVELOPMENT

TEXTILE DESIGN

ADVERTISEMENT CAMPAIGNs

BROCHURES AND SALES COLLATERAL

BRAND CURATION

Direct Promotions is full service design agency and print production facility

located in Sunset Park, Brooklyn. One of the top New York Board of Education

contract holders in NYC, Direct Promotions has the proven expertise to help

your company or organization deliver a corporate message, create the latest

fashion trend, promote your special event, display your team pride, or

personalize life’s biggest moments.

Using the latest printing & embroidery technology for the top-notch products you are looking for and the web technology to streamline the distribution and fulfillment process that saves your time and hassle, we are capable of printing & shipping over 24,000 items a day, which most competitors just cannot compare.

Throughout my role as Art and Digital Printing Director, I have significantly impacted project management, production efficiency, and team leadership. I led cross-departmental 360 campaigns, streamlined inventory and production management through the Siteflow system with HP, and maintained cost efficiency and quality across various production equipment. I effectively presented creative concepts to internal teams, directed successful Shopify and Etsy brand web stores that increased profits by 20%, and managed a team of 15 across design and production, fostering collaboration and efficiency.

Doe branding Collateral

PATTERN AND TEXTILE DESIGN

HOME GOODS production

THE SLANT GLASS

During my time at direct promotions I face many challenging production projects. I choose to highlight this specific project to showcase how I utilize my experience and knowledge to provide solutions for bringing complex products to market

in 2022, Uncommon Goods reached out to us asking if we can produce this skier glass set for them. Given the unique shape of this glass many custom fabrication solutions needed to be developed to be able to mass produce this product. The following slides will document all the challenges we faced from print preparation to shipping.

Pre-Production Solutions

In order to print on this glass with our Helix UV printer, the glassware must first be coated for proper adhesion. We normally out source this part of the process, but none of our supplies were willing to put this glass through their machines. So we acquired a Inkcups MagiCoat™ system and brought the process in house. I also had to design and fabricate a custom jig system to hold the vessel for our Helix printer.

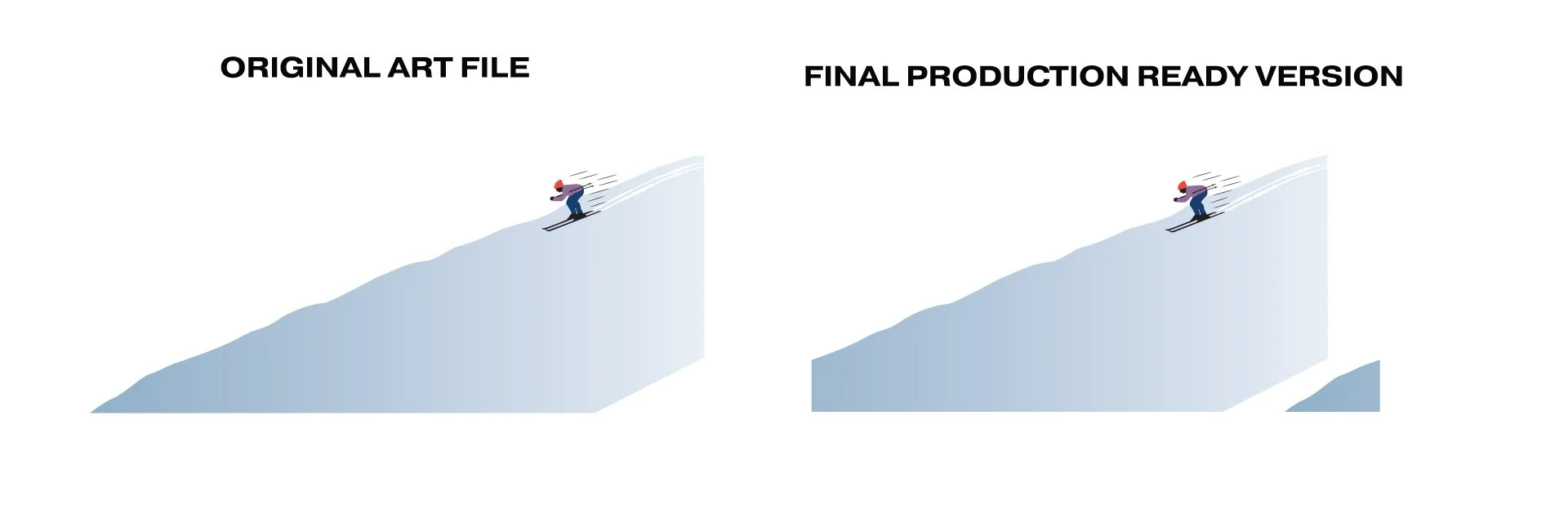

ARTWORK SETUP

Since the glass is at such a slanted angle, we had to alter the artwork in order to uniformly match across the set. We had to slightly warp and break up the graphic within the print template space to allow it to wrap correct;y. This process needed to be repeated for each of the four graphics in the set.

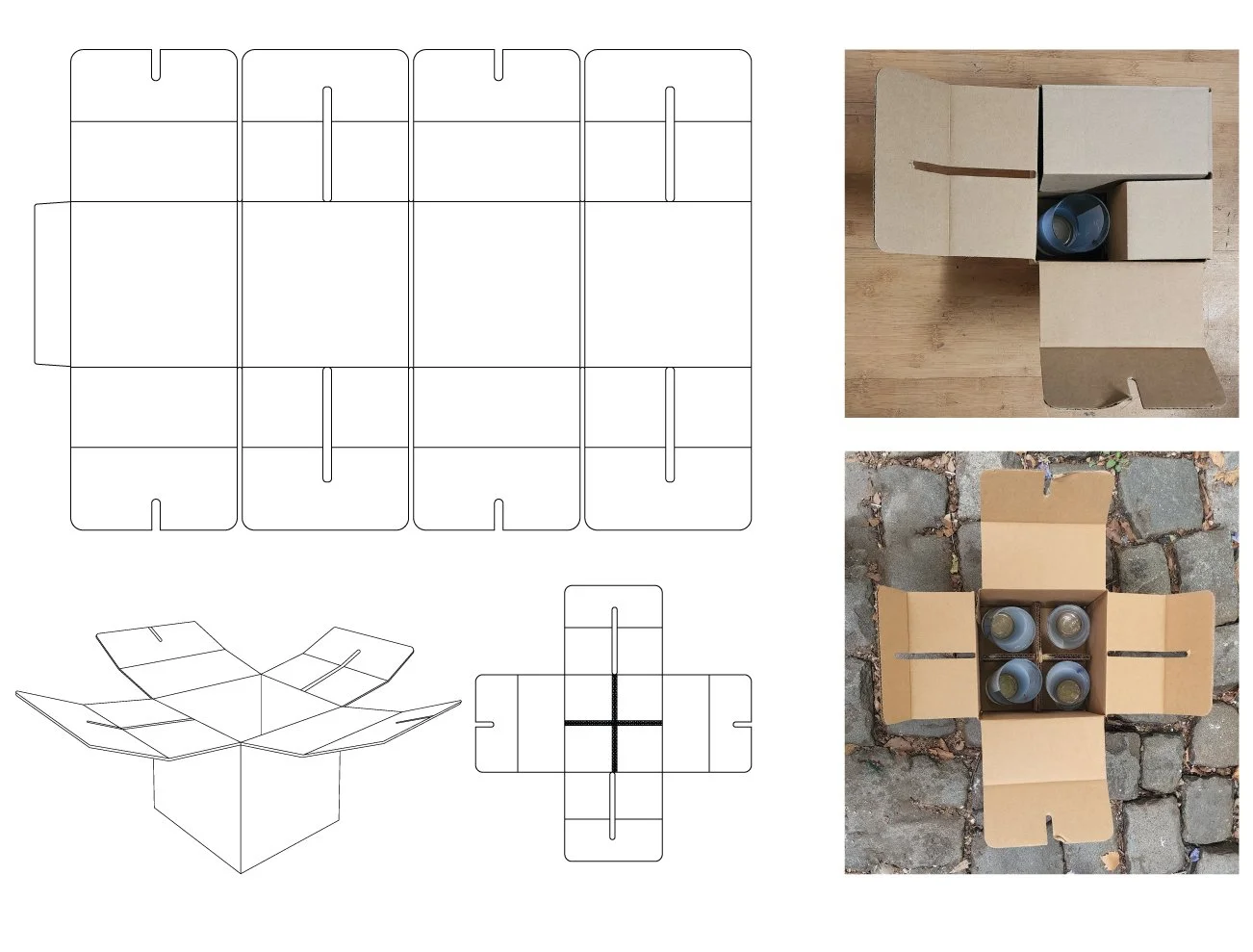

PACKAGING

This is the custom shipping box template that was created for this glass set, because of course with its unique shape no standard box would fit properly. The top and bottom sections of the box interlock together to from a barrier between each glass. Once stuffed and bubble wrapped these compartments allows each glass to remain stable and secured for abuse in transit.

Final Product shots

This project took place over 3 months and allowed us to developed new production processes that is now used across many products. It relied on my direction of several departments within the company and a few outside vendors to bring to fruition. In the fourth quarter of 2022 we produced over 20,000 sets of these glasses, proving that our process worked at scale, on budget, on time, and is still a high seller in their product line.

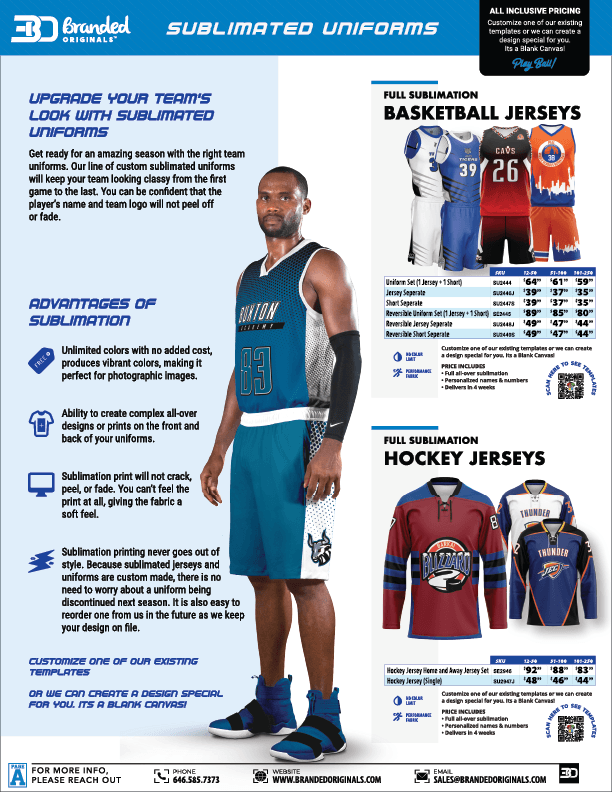

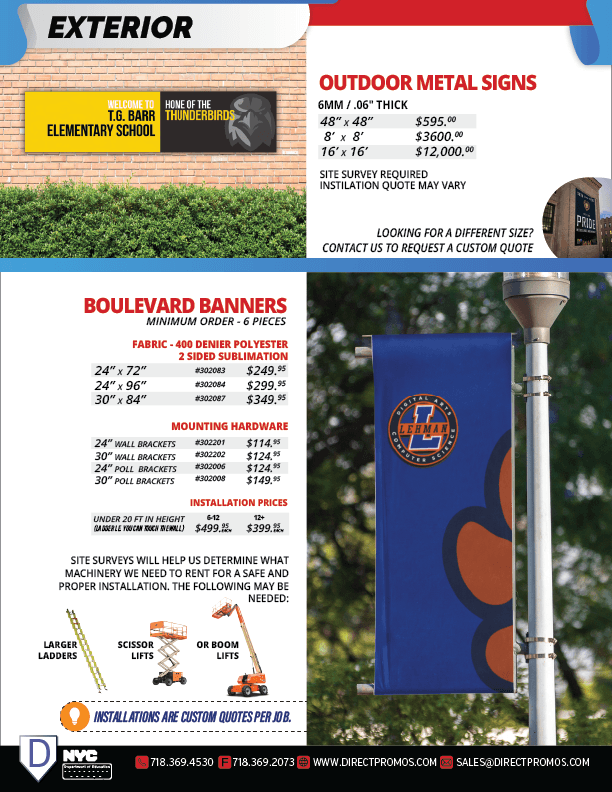

SALES BROCHURES AND MARKETING CATALOGS

below are some of the many sales brochures, tri-folds, and catalogs were regularly sent to our clients that I worked on.